Products

We are a leading manufacturer of quality internal and external lighting products for commercial, industrial and retail applications.

View all productsProduct Types

Sectors

At Ansell Lighting we design and manufacture an extensive range of luminaires for a diverse number of sectors and applications. Whatever the shape, purpose or style of your space, we have a lighting solution.

View all sectors & applicationsSectors & Applications

About Us

We are a leading manufacturer of quality internal and external lighting products for commercial, industrial and retail applications.

Welcome to Ansell lightingAdvice and information

Contact

We are here to answer any questions you may have, help you find a stockist or speak to a local member of our team.

Find out more

OCTO

OCTO delivers the complete smart lighting package to transform the efficiency and ambience of commercial and residential spaces.

Commercial & Residential Smart Lighting and OCTO Insight

Support & Training

Find information regarding our product warranty, product data downloads and FAQs regarding lighting and technical terms. Here you will find support with training CPDs as well as useful lighting design and LED strip calculators.

Warranty information, CPD training, calculators, and FAQs

Microwave Vs Passive Infrared Detection

Sensors play a key role in lighting control systems delivering on both efficiency and usability and offering a number of practical and security benefits by detecting human presence and enabling lights to be used only when needed.

The two most used technologies in residential settings, offices and industrial spaces are microwave and PIR (Passive Infrared) sensors. But which one is right for your project? Here we look at how each technology works and the advantages and disadvantages of each.

Passive Infra-Red Detection

A Passive Infra-Red Sensor, commonly referred to as a PIR, is an electronic sensor which measures the infrared radiation being detected from objects within its field of view and is generally used for the automatic activation and control of lighting equipment as well as in security alarm systems.

Although often referred to as motion detection, a PIR sensor does not detect movement, but operates utilising by detecting change of heat, by measuring infrared radiation, not visible to the human eye, contained within its field of view.

The PIR sensor has two Infra-Red Sensitive Slots, made from a specialised material sensitive to infrared radiation. Under normal operating conditions, the sensor remains in an idle state, with both the InfraRed slots synchronised and aligned to detect equal amounts of infrared radiation within the space. When a warm body (person!) moves across the space, one half of the sensor intercepts the change, which causes a positive differential change between the two halves of the sensor activating and switching on lighting equipment. When the warm body has left the space the sensor generates a negative differential change, returning the equilibrium and alignment between the two halves of the sensor, and the light is deactivated.

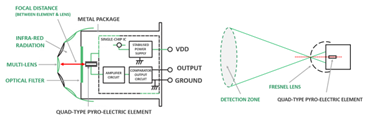

As a more technical explanation – a PIR consists of three components: the electronic circuitry contained within the unit; the pyro-electric sensor; and the Fresnel Lens. The circuitry processes the output of the pyro-electric sensor to determine when a change is observed – indicating movement within the space. The pyro-electric sensor is an analogue device with two detector elements, one being wired so that upon receipt of infrared radiation, it emits a low voltage and the other to emit a high voltage. When equilibrium is in place, both receive equal amounts of radiation, meaning the emitted voltage is therefore also equal, resulting in the lighting being in an off state.

The Fresnel Lens is the visible part of the sensor where the infrared radiation is received and focused onto the sensor. The lens is segmented so that multiple beams of infrared radiation can be received, each corresponding to a separate segment within the field of view. The design of the lens is massively important, as it determines the beam width and range of detection, as well as the sensitivity of the PIR Sensor.

When movement is detected, the low and high voltages within the pyro-electric sensor change, and activating the lighting equipment.

Microwave Detection

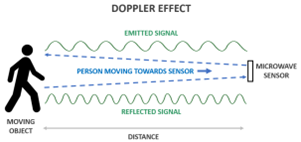

A Microwave Sensor used to control lighting equipment is an active device that emits several very low-level pulses of electromagnetic radiation, which strike a target and are then bounced back to the receiving sensor.

The active device utilises the ‘Doppler Effect’ to analyse the received information and determine if there is a moving object within the area and therefore turn on the lighting equipment.

In lighting control applications the use of microwave is an ideal solution for occupancy or motion sensing because the waves are low energy, as well as being both invisible and inaudible. Any deviation between the frequency of the radiation, emitted by the sensor and the received frequency, indicates movement within the space. If the received frequency is higher, the object is moving towards the sensor, whereas if it is lower, the object is moving away from the sensor.

There are two versions Microwave sensors – Monostatic, where the sensor is contained within one unit, and Biostatic, where the sensor is contained in two units. Lighting applications usually utilise a monostatic units as they are smaller and therefore easier to integrate into light fittings, making them less visible and more aesthetically pleasing. They work with a variety of different light sources including solid state lighting (LED) and operate very efficiently through the fitting diffuser, meaning that holes do not need to be cut into the luminaire body and so do not affect the ingress protection rating of the luminaire.

Advantages and Disadvantages

PIR Sensor Advantages

- Deemed to be more energy efficient than other sensors, using approximately 1.0Watt, compared to around 1.5Watts for the Microwave Sensor.

- As a passive device it does not release any electromagnetic wave and so there is no interference when operating around sensitive testing equipment

- Lower initial purchase cost, making it ideally suited to smaller applications.

- Less prone to being triggered by non-human sources of movement, such as curtains or foliage due to reliance on heat changes rather than movement

PIR Sensor Disadvantages

- A PIR sensor is not generally programmed to be constantly sensing, being designed to cycle, which means the light must be fully switched off by the sensor, before it has the capability to start sensing again, generally because the emitted light may be deemed to interfere with the actions of the sensor.

- The sensor can be insensitive to detection when either a person is walking directly towards it or when both the ambient space and the person are at the same temperature.

- Being under sensitive within locations of higher background temperatures and over sensitive within locations of lower temperatures

- Influenced by sudden shifts in ambient temperature and external influences, such as wind, potentially leading to false alarms or overlooking detections.,

- Shorter detection range compared to microwave sensors, which may pose a challenge in expansive or open environments.

Microwave Sensor Advantages

- Can be installed into virtually any environment, including areas of high heat, or where the environment can damage photo-electric sensors.

- Can penetrate through walls and glass windows, so deemed to have a wider area of detection, including large outdoor spaces

- Can be set to be constantly sensing for movement and therefore do not turn off in a space of high usage, delivering consistent detection over all temperatures.

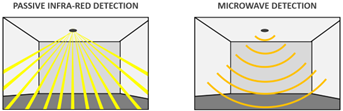

- A microwave sensor has a continuous field of detection zone and is therefore capable of detecting more subtle movements, whereas a PIR sensor has a slotted detection zone

Microwave Sensor Disadvantages

- While the ability to penetrate walls and glass windows can be seen as a benefit, a microwave sensor cannot penetrate metal objects, which may be a concern for metal constructed buildings. It also means it has an inability to detect movement in areas behind metal objects located within the space.

- The capability of detection through walls and glass can result in multiple false detections from adjacent spaces, or where a building is located adjacent to a main road, large box type vehicles and buses may also cause multiple false detections.

- More expensive to purchase and more expensive to operate. The signals of microwave sensors can be affected by other electronic devices emitting radio waves, diminishing their effectiveness in certain scenarios.

Conclusion

False triggering can be a concern for lighting installations as well as security alarm systems, so using a combination of technologies within a single sensor application or using two separate sensors of different types for the same operation, can help. In a lighting installation, for the lighting equipment to be activated, both cells within the single sensor or both the separate sensors, when wired together, must provide the combined activation signal to activate the lighting, therefore reducing instances of false activation, preventing unwanted usage and potentially reducing the energy consumption of the lighting installation.