The classification of the degree of protection provided by enclosures, including those containing electrical lighting equipment against mechanical impact.

The term ‘IK’, where the ‘K’ part stands for ‘Kinetic’ relates to the motion of material bodies and the forces of energy associated with them.

IK ratings are defined as IKXX, where “XX” is the number from 00 up to 10, indicating the degree level of protection provided by the enclosure, which includes those containing luminaires, against external mechanical impacts.

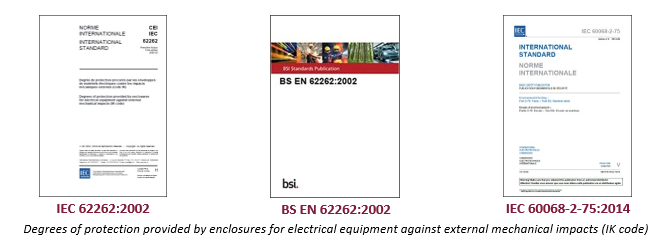

IEC 62262:2002 and BS EN 62262:2002 describe a system for classifying the degrees of protection provided by enclosures for electrical equipment against external mechanical impact (IK Code). Whilst this system is suitable for use with most types of electrical equipment, it should not be assumed that all the listed degrees of protection are applicable to a particular type of equipment.

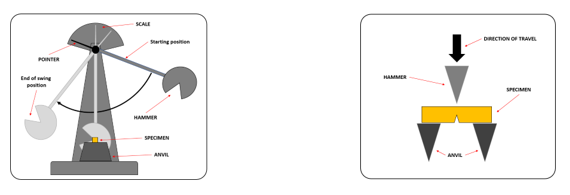

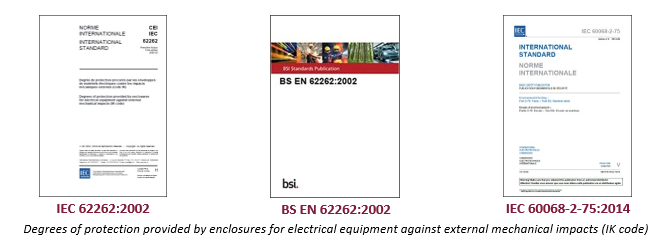

IEC 60068-2-75:2014 provides further detail where this part of IEC 60068 provides three standardized and coordinated test methods for determining the ability of a specimen to withstand specified severities of impact. It is used, in particular, to demonstrate an acceptable level of robustness when assessing the safety of a product and is primarily intended for the testing of electrotechnical items. It consists of the application to the specimen of a prescribed number of impacts defined by their impact energy and applied in the prescribed directions. This part covers energy levels ranging from 0,14j (joules) to 50j (joules).

The degree of protection applies to the complete enclosure and testing is carried out within a temperature range of 15°C - 35°C at an atmospheric pressure of between 860mb and 1060mb and is based upon testing of a new enclosure and to verify protection against mechanical impact, blows shall be applied to the enclosure being tested which is based upon 5 impacts to each face of the enclosure.

IK ratings are defined as IKXX, where “XX” is the number from 00 up to 10, indicating the degree level of protection provided by the enclosure, which includes those containing luminaires, against external mechanical impacts. This is of importance when considering the installation of lighting equipment for the more arduous applications, such as in sports centres and also outdoor working areas, such as in construction.

The different levels of IK ratings relate to the ability of the enclosure to resist varying impact energy levels measured in joules (j) and the International Electrotechnical Commission document, IEC 62262:2002 denotes how protected an enclosure (light fitting) is from mechanical impact, with the ratings at the higher end providing greater tolerance for impact. The British Standard version is BS EN 62262:2002 and is the UK version of the EN Standard, which in turn is the European version of the international standard.