See how much you could save on energy costs with our easy-to-use LED Energy Calculator.

Open Energy CalculatorWe design and manufacture an extensive range of luminaires for a diverse number of sectors and applications. Whatever the shape, purpose or style of your space, we have a lighting solution.

View all sectors & applicationsView our latest product, OCTO smart lighting and application sector brochures.

Download our BrochuresFind information regarding our product warranty, product data downloads and FAQs regarding lighting and technical terms. Here you will find support with training CPDs as well as useful lighting design and LED strip calculators.

View the Energy CalculatorOCTO delivers the complete smart lighting package to transform the efficiency and ambience of commercial and residential spaces.

Download the BrochureFind product warranty details, data downloads, and lighting FAQs. Access training CPDs plus handy lighting design, energy and LED strip calculators—all in one place.

View the Energy CalculatorThe basics of LED thermal management

There are those who believe that operating LED lamps and LED luminaires within lighting applications provides the user with a cool to touch scenario, where there is minimal transfer of the consumed energy into heat, however this is not the case as more appropriately, these light sources are usually referred as cool, because the spectral output of an LED used for illumination does not contain infrared radiation, whereas incandescent and halogen lamps produce a sizeable amount of infrared radiation.

Whilst it is widely accepted, that the development of the LED light source has revolutionised the lighting industry, in providing the opportunity for lighting to have a reduced energy consumption to achieve the required levels of illuminance, which in some cases may be as little as 10%, when replacing incandescent GLS lamps or halogen display lamps for LED alternatives.

All light sources transfer a portion of the consumed energy used into heat, where the GLS incandescent lamp is only around 5% efficient, meaning that 95% of the energy is given off as a by-product in the form of heat, whereas, it is generally accepted that LED light sources are approximately 45% efficient in the conversion of electrical energy to visible light, which means that the remaining 55% of energy is in the form of heat, however one should remember that this scenario is based upon the significantly reduced level power consumption.

For an LED light source, heat is transferred between the elements in two different ways, that of thermal conduction and thermal convection, however there is also thermal radiation, which for an LED lighting system, contributes very little to heat transfer since the surface temperatures are relatively low and most LED luminaires have a small surface area.

Thermal conduction is the transfer of energy from a higher temperature region to a lower temperature region across a solid material by direct contact until a point where thermal equilibrium is reached between the two regions and is dependent upon the thermal characteristic of the materials being used. The optimum thermal conduction capacity is best achieved by maximising the thermal conductivity of the material and in its effective surface area, where materials, which are metal based, provide the best thermal conductors. Conduction is a significant mechanism of heat transfer within an LED lighting system in which solid components are designed to be in mechanical contact.

Thermal convection is the transfer of heat through the physical movement of molecules from the boundary of a solid matter to a fluid, but is normally direct into the ambient air, and the amount of convective heat transfer depends upon an effective surface area and the mobility of the air within the vicinity. Thermal convection is as a result of gravitational flow by way of natural passive convection, which in some cases can be facilitated externally through active cooling by the use of mechanical means within luminaires, a system known as forced convection. In LED systems, convection is the main mode of heat transfer for removing the heat from the LED heat sink into the ambient air.

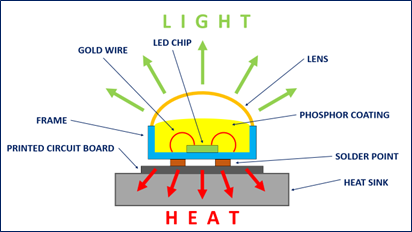

Typically, the LED chip is surface mounted onto a printed circuit board (PCB) and requires that the significant amounts of heat being generated needs to be dissipated and transferred through the bottom of the LED chip to the PCB by way of the soldered interconnections, and where the thermal performance and reliability between the LED chip and the PCB board is critical to allow for the effective heat transfer through thermal conduction.

The transfer of heat from the LED package to the heat sink is also critically important, where thermal interface materials are used to fill the air gaps and voids between the heat sink and the PCB, as air is a poor conductor, thereby possibly undermining the efficiency of the thermal conduction route for heat dissipation. The heat sink is a high thermal conductive device, designed and constructed to have a sizeable maximum surface area, which then allows for the provision of effective heat dissipation through thermal convection.

The heat sink is considered to be the final and most influential part of the thermal management route of an LED system, where many heat sinks utilise a range of ‘fins’, to optimally maximise the surface area for convection cooling, as when operating LEDs at fairly high drive currents with higher ambient temperatures, alongside not compromising the lumen performance of the light source or the reliability of the circuit, this will require fast and efficient removal of heat from the junction point into the ambient environment.

In order to facilitate the required high volumes of thermal conduction through the heat sink, the materials used for the construction process of the luminaire heat sink is therefore an important consideration. The use of aluminium at between 90W/mK and 240W/mK, (Watts per metre Kelvin) offers significant advantages as a heat sink material, in having high dimensional stability, extensive thermal conductivity levels, excellent resistance to corrosion, ideal finishing characteristics, and having reduced weight properties, alongside the provision of full recyclability and sustainability, together with an acceptable level of cost. The heat sink is designed to extract heat into the ambient surrounding air, through thermal convection, so as to maintain an appropriate junction temperature for the LED, which will continue to operate optimally within defined and safe limits.