See how much you could save on energy costs with our easy-to-use LED Energy Calculator.

Open Energy CalculatorWe design and manufacture an extensive range of luminaires for a diverse number of sectors and applications. Whatever the shape, purpose or style of your space, we have a lighting solution.

View all sectors & applicationsView our latest product, OCTO smart lighting and application sector brochures.

Download our BrochuresFind information regarding our product warranty, product data downloads and FAQs regarding lighting and technical terms. Here you will find support with training CPDs as well as useful lighting design and LED strip calculators.

View the Energy CalculatorOCTO delivers the complete smart lighting package to transform the efficiency and ambience of commercial and residential spaces.

Download the BrochureFind product warranty details, data downloads, and lighting FAQs. Access training CPDs plus handy lighting design, energy and LED strip calculators—all in one place.

View the Energy CalculatorTesting of emergency lighting to retain compliance

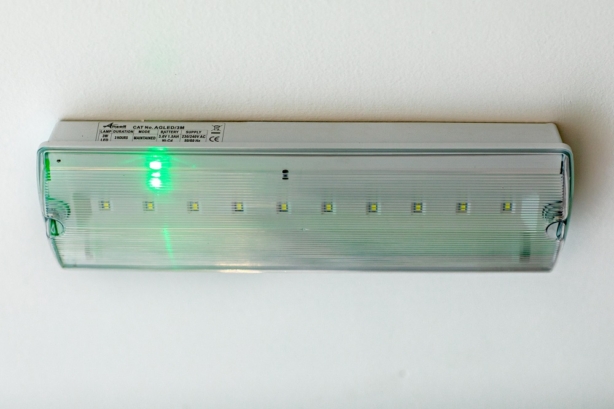

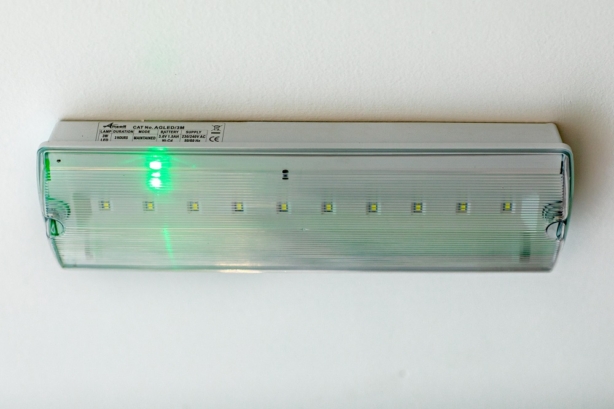

Emergency lighting is installed for use when the power supply to the normal lighting fails and therefore must be powered from a source independent of that supplying the normal mains lighting. The procedure for the testing of the emergency lighting within buildings is a mandatory requirement, so as to allow occupants the opportunity to escape safely in the event of an emergency.

The failure to provide appropriate emergency lighting, which is adequately maintained in compliance of the relevant standards, has come into news broadcasts over recent years, where the owners of properties have been subject to prosecution for non-compliance, either for the provision of having installed inadequate emergency lighting or in the failure to carry out the required testing procedure so as to ensure the equipment continues to work optimally, and in the event of a requirement for its use, will operate as designed and allow all persons safe egress from the building.

According to BS EN 50172:2004, the purpose for the provision of emergency escape lighting is to ensure that lighting is provided both promptly and automatically, and for a suitable duration of time, upon the failure of the power supply to the normal lighting. Additionally the emergency lighting is to fulfil the functions of illuminating the escape route signs, to provide illumination along such routes as to allow safe movement towards and through the exits provided so as to get to a place of safety and to ensure that fire alarm call points and fire equipment provided along escape routes can be readily located and used. It is to also permit operations concerned with safety measures. Emergency escape lighting shall be activated not only on complete failure of the supply to the normal lighting but also on a localised failure such as with a circuit failure.

Within BS 5266-1:2016, there is a requirement that emergency lighting systems should be inspected and tested at regular intervals in accordance with BS EN 50172 whereas within BS EN 1838:2013, it is to ensure that emergency escape lighting operates when it is required to meet legal requirements, where it shall be installed, tested and maintained in accordance with BS EN 60598-2-22, BS EN 50172 and BS EN 62034.

For those, who have taken the time to read the recent editorial on Emergency Lighting, will have concluded that BS5266-1:2016, is the code of practice for the emergency lighting of premises and as such its presentational conventions use the verb of ‘should’, which means it is a code of practice, whereas, BS EN 1838:2013 on lighting applications for emergency lighting and BS EN 50172:2004 on emergency escape lighting systems are defined by their presentational conventions using the verb of ‘shall’, which means, these documents are standards.

With regard to routine inspections and tests, BS 5266-1:2016 states that the emergency lighting systems should be inspected and tested at regular intervals in accordance with BS EN 50172 and where a functional operation should be checked at least every month. The testing of full rated duration should be performed on each emergency luminaire at least annually where precautions should be taken during the full rated duration tests to either perform the test while the building is empty or at times of minimal risk or to only test alternate luminaires at any one time so that the building has a charged luminaire adjacent to the unit under test. Additionally, a visual inspection should be performed on each luminaire at least annually.

Within BS EN 50172:2004, where the detail on emergency escape lighting system records and reporting requires that upon completion of the installation, drawings of the emergency escape lighting shall be provided and be retained on the premises. They shall identify all luminaires and main components, shall be regularly updated with any subsequent changes to the system and these drawings shall be signed by a competent person to verify that the design meets the requirements of the standard. In addition, the standard states that a logbook shall be provided for the recording of routine examinations, tests, defects and alterations and these shall be available as either a manual record or as a hard copy obtained from an automatic testing device.

Upon completion of an inspection and test schedule as required in the periodic inspection, a logbook shall be kept on the premises in the care of a responsible person appointed by the occupier/owner and shall be readily available for examination by any duly authorised person and shall be used to record the date of commissioning of the system including any certificate relating to alterations, the date of each periodic inspection and test, the date and brief details of each service, inspection or test being carried out, the dates and brief details of any defects and of remedial action taken, the date and brief details of any alteration to the emergency lighting installation and if any automatic testing device is employed, the main characteristic and the mode of operation of that device shall be described.

The following minimum inspections and tests shall be carried out at the intervals recommended and the regulating authority may also require additional specific tests.

Daily – Indicators of central power supply shall be visually inspected for correct operation and this is a visual inspection of indicators to identify that the system is in a ready condition and does not require a test of operation.

Monthly – If automatic testing devices are used, the results of the short duration tests shall be recorded, and the tests shall be carried out by switching on, in the emergency mode for each luminaire and each internally illuminated exit sign from its battery by simulation of a failure of the supply to the normal lighting for a period sufficient to ensure that each lamp is illuminated. During this period, all luminaires and signs shall be checked to ensure that they are present, clean and functioning correctly and at the end of this test period, the supply to the normal lighting should be restored and any indicator lamp or device checked to ensure that it is showing that the normal supply has been restored where the period of simulated failure should be sufficient for the purpose of this clause whilst minimising damage to the system components, such as lamps.

Annually – If automatic testing devices are used, the results of the full rated duration test shall be recorded, however, for all other systems, the monthly inspection shall be carried out and additional tests made where each luminaire and internally illuminated sign shall be tested for its full rated duration in accordance with the manufacturer’s information. The supply of the normal lighting shall be restored, and any indicator lamp or device checked to ensure that it is showing that normal supply has been restored and the charging arrangements should be checked for proper functioning. The date of the test and its results shall be recorded in the system logbook.

Additionally from BS EN 50172:2004, and due of the possibility of a failure of the normal lighting supply occurring shortly after the period of the emergency lighting system testing procedure or during the subsequent recharge period, all full duration tests shall wherever possible be undertaken at times of low risk to allow for battery recharge or alternatively, suitable temporary arrangements shall be made until the batteries have been fully recharged.

Having made a significant investment to incorporate the installation of emergency lighting into the construction of the building, it is important that the testing procedure is undertaken in compliance with the appropriate standards. In doing so, this will protect the users and allow all safe egress from the building in the event of a fire or emergency, as it is the protection of life, which is the most critical aspect of undertaking the appropriate testing requirement.

You Might Also Be Interested In...