See how much you could save on energy costs with our easy-to-use LED Energy Calculator.

Open Energy CalculatorWe design and manufacture an extensive range of luminaires for a diverse number of sectors and applications. Whatever the shape, purpose or style of your space, we have a lighting solution.

View all sectors & applicationsView our latest product, OCTO smart lighting and application sector brochures.

Download our BrochuresFind information regarding our product warranty, product data downloads and FAQs regarding lighting and technical terms. Here you will find support with training CPDs as well as useful lighting design and LED strip calculators.

View the Energy CalculatorOCTO delivers the complete smart lighting package to transform the efficiency and ambience of commercial and residential spaces.

Download the BrochureFind product warranty details, data downloads, and lighting FAQs. Access training CPDs plus handy lighting design, energy and LED strip calculators—all in one place.

View the Energy CalculatorLighting – The MacAdam Ellipse and Colour consistency

Within the lighting industry, the process of the sorting and categorisation of LED’s is done by considering a number of characteristics, such as colour, voltage and brightness of the LED’s and to that end the International Commission on Illumination (CIE) first developed the 1931 (x,y) mechanism based upon colour spaces and the CIE 1931 chromaticity diagram provided a methodology for mapping the perceived colour onto the unit plane of an ‘x’, ‘y’ graph. A pair of chromaticity coordinates for the light source corresponded to a unique colour point of light.

The human visual system is absolutely unique for each individual and around the early 1940’s, the research undertaken by David Lewis MacAdam, whilst working at Kodak in their research laboratory, determined that an observer could match colours within a consistent statistical range and using this method, he could show a plot of this range on the CIE (x,y) colour space diagram, with the results depicting an elliptical area of colour where an observer would identify these as being the same. The MacAdam ellipse, as it later became known, has been used to define the colour point specification of lamps well before the introduction of LED’s, and with the technology change to Solid State Lighting, it’s use is becoming even more prevalent where LED binning becomes essential. It provides the guidance as to how accurately show a person’s colour vision, and how good they are at the ability to distinguish between similar colours.

It’s use is as a measure of colour difference and has become common practice in the lighting industry, continuing to be so, in that, it defines a zone in the CIE (x, y) colour space within which people are able to distinguish the colour variations within a specific range of colour temperatures.

The scale of a MacAdam ellipse is defined as a plane diagram in which points specified by chromaticity coordinates which represent the chromaticities of colour stimuli (CIE) which is termed as being the SDCM which stands for Standard Deviation of Colour Matching.

|

|

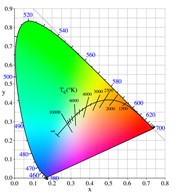

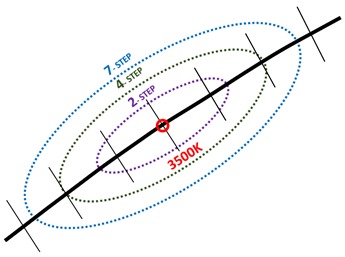

| CIE 1931 Chromaticity Diagram | MacAdam Ellipse centred at 3500K (sample plot) |

The CIE Chromaticity Diagram describes the colour of light and the left-hand image shows a colour diagram which is in general use today. It is a diagram of reference for colour points with wavelengths shown around the upper edge given in nanometres (nm), within the electromagnetic spectrum giving a range of values from 380nm to 700nm.

The fundamental way of describing colour as given by the CIE in which the ‘x’ and ‘y’ values describe the chromaticity or colour of the light source, with a ‘z’ value describing the brightness. The colour can be simply specified by giving the ‘x’ and ‘y’ coordinates.

Within the ‘x’ ‘y’ chromaticity space, the line drawn across it represents the colour that an incandescent black body would appear to radiate with changes to the increase of decrease in temperature given in Kelvin (K). This line is the ‘black body locus’ or ‘Planckian locus’ and the lines crossing indicate the lines of constant colour temperature (<5000K) and correlated colour temperature (>5000K) where the colour is perceived to most closely resemble that of the ideal value. Whilst the colour temperature (Tc(K)) curve shown above indicates values from 1500K to 10000K, the common lighting values are between 2700K and 6500K.

The displayed right-hand image shows the MacAdam ellipses which are categorised with step sizes, generally given from 1 Step to 7 Steps, where the larger the number, the larger the tolerance of colour difference, however in this sample diagram, there is 3 values shown at 2-SDCM, 4-SDCM and 7-SDCM. These values were selected, not by random, but as being the most common seen on lighting products, however other values can be included, where required, inside the 7-SDCM ellipse. The range of colour temperature for this 3500K light source shown above, with a 7 Step MacAdam ellipse provides approximately a 200-250K colour difference above and below the focal point, which results in a potential range difference from around 3300K up to around 3700K for this sample light source of 3500K.

A 1-Step MacAdam ellipse is defined as being ‘1-SDCM’, with a 2-Step MacAdam ellipse being defined as 2-SDCM and so on up to a 7-Step MacAdam ellipse as 7-SDCM. It is considered that the human eye cannot distinguish any difference in colour temperature where the chromaticity coordinates are provided as being within 1-SDCM or one Step MacAdam ellipse, however when you get to 2-SDCM, the difference has barely the ability to be distinguished by the trained human eye, even though the values for standard deviation of colour matching have doubled from the previous value.

For lighting specifications, the range of values of Standard Deviation of Colour Matching (SDCM) are normally between that of 2-SDCM and 7-SCDM, with 1-SDCM being unachievable on a practical basic and, where the lower values equal to 2-SDCM to 3-SDCM are usually specified for lighting applications where more control of the colour consistency is required. These are generally for installations where colour matching is a prerequisite and where the colour consistency of the lighting is critical for the task being undertaken, however it still may be possible to see some small amount of colour variation in the light source in these instances.

For more general internal lighting installations, a value of around 3-SDCM to 4-SDCM can be the accepted value, however a greater shift of colour will sometimes be visually distracting and can create the impression of a poorly designed space or one which is not adequately maintained. This can occur in applications such as car showrooms and departmental stores selling fabrics where the wider SDCM can reduce colour consistency, making it difficult to determine the true colour of the product. It is also important to consider the budget limitations of the application as products with a lower SDCM value may attract an incremental increase in purchase cost.

When designing interior applications such as residential or for exterior lighting projects, a value at the higher end of either 5-SDCM to 7-SDCM is normally assumed to be the acceptable solution, being a trade-off between the benefits of colour consistency and that of any budget constraints.

Colour and with it, the ability to determine and discriminate between different colours is an important consideration of electric lighting, as when you are looking to make the purchase an item, such as a new car for instance, you want to be completely sure that the colour of the car being offered and viewed in the well internally illuminated showroom, is in fact displaying its true colour.

You Might Also Be Interested In...