See how much you could save on energy costs with our easy-to-use LED Energy Calculator.

Open Energy CalculatorWe design and manufacture an extensive range of luminaires for a diverse number of sectors and applications. Whatever the shape, purpose or style of your space, we have a lighting solution.

View all sectors & applicationsView our latest product, OCTO smart lighting and application sector brochures.

Download our BrochuresFind information regarding our product warranty, product data downloads and FAQs regarding lighting and technical terms. Here you will find support with training CPDs as well as useful lighting design and LED strip calculators.

View the Energy CalculatorOCTO delivers the complete smart lighting package to transform the efficiency and ambience of commercial and residential spaces.

Download the BrochureFind product warranty details, data downloads, and lighting FAQs. Access training CPDs plus handy lighting design, energy and LED strip calculators—all in one place.

View the Energy CalculatorLED Strip – A Technical Look

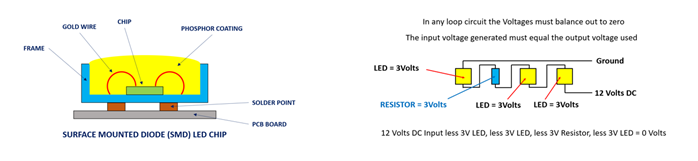

‘LED Strip’, sometimes referred to as ‘LED Tape’ is a well-known and often used lighting solution being based upon a number of LED surface mounted diodes, referred to as SMD chips, and is currently considered as being the most common light source used for LED Strip. The LED chip is mounted onto a flexible circuit board, where there can be more than one diode within the chip, and with the potential for each diode to have its own circuit.

Having a LED chip containing 3 separate diodes, where each diode operates on a separate circuit, facilitates the opportunity of creating colour by using single red, green and blue diodes within the chip to create a RGB light source.

The SMD chips are categorised using a four-digit number, which relates to their square or rectangular dimensions, where the maximum size of an SMD chip is generally considered as being 5.7mm x 5.0mm. The two most common sizes are SMD3528, being 3.5mm x 2.8mm and SMD5050 being 5.0mm x 5.0mm. The LED chips are mounted onto the circuit board, which is constructed in linear lengths, thereby creating the LED Strip, and providing an ideal solution for accent or feature lighting for many different applications, both internally and externally.

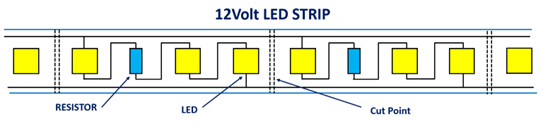

The majority LED Strip operates using a Direct Current (DC) circuit, being offered in either 12 Volt, 24 Volt or 48 Volt derivatives, each of which has sufficient power to illuminate multiple LEDs contained within an individual circuit on the LED Strip. Generally, the SMD LED is a 3 Volt device, which will illuminate when a differential voltage of 3 Volts is applied across the chip, with the specified voltage of the LED Strip being then determined by the number of LEDs and Resistors used in each of the individual Series circuits. For the example shown below, within a 12 Volt circuit, there is usually 3 LEDs alongside a 3 Volt Resistor, whereas for a 24 Volt LED circuit, there is 6 LEDs with a 6 Volt Resistor and for a 48 Volt circuit, there is 12 LEDs with two 6 Volt Resistors, all installed in a Series circuit format.

Each of the individual Series circuits are mounted onto the LED Strip circuit board, and then the multiple Series circuits are connected together, being then wired in parallel along the length of the LED Strip, and where the length of each individual Series circuit defines the distance between the linear cutting points. The LED Strip will usually be marked to show where the individual circuit starts and finishes, normally with a ‘scissor’ icon, allowing the LED Strip to be cut at any of those points so as to retain full illumination, however, if a cut is made elsewhere, the cut part of the final Series circuit will not illuminate, as the completed individual circuit will have been cut. The LED Strip is then connected to a Constant Voltage Driver of the same secondary voltage and appropriate current rating based upon the output and length of the LED Strip being operated through it.

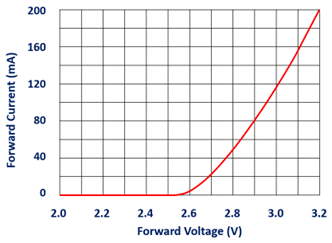

Before looking to discuss the terms used in the graph diagram shown towards the end of the editorial, it may prove beneficial to discuss them in more detail. The text and diagram below will hopefully offer some explanation.

The term ‘Forward Voltage’ (Vf) is the amount of voltage required in the circuit to allow the current to flow through the LED(s) and if the voltage is too low, the circuit will remain in an ‘open’ state, which means the current will not flow and the LED(s) will not be illuminated. According to Kirchhoff’s second law on voltage, ‘the directed sum of the potential differences around a closed loop is zero’, where the potential differences equate to the difference in voltage.

The term ‘Forward Current’ (If) is the current which flows across the LED from the anode to cathode, allowing the LED to receive sufficient current to switch on and illuminate. The LED(s) will use all of the available forward current supplied and the installation of a resistor, placed in Series within the circuit restricts the current going through the LED(s), According to Kirchhoff’s first law, on current, ‘the algebraic sum of currents in a network of conductors meeting at a point is zero’. The correct term for the resistor item used in the circuit is a ‘Current Limiting Resistor’.

The constructed graph below provides an indication of the relationship between the forward voltage being passed though the LED and the forward current being drawn through the circuit, where the forward voltage of an LED is the positive voltage which is to be applied across it from the anode to the cathode for the LED to illuminate. For the LED Strip image shown above, each part of the 12 Volt Series circuit encompasses 3 LEDs and a Resistor, with the single LED being rated at 3 Volts. The forward current of an LED relates to the current which flows across the LED from anode to cathode, for it to receive sufficient current to power on.

Also shown within the graph above, is that for a 12 Volt LED circuit, the forward current, when operating at 12 Volts, is 120 mA, however if the individual circuit experiences a volt-drop over the length of the installed LED Strip, which will result in a reduction of the secondary voltage from 12 Volts to, say, around 11 Volts, where each of the LED now receives a proportionately reduced voltage of approximately 2.75 Volts, which in turn, from the graph curve, reduces the forward current to 40 mA. The circuit will continue to operate safely, however the amount of illumination produced from the LED circuit will be reduced, making the light appear somewhat dimmer at that point along the LED Strip.