See how much you could save on energy costs with our easy-to-use LED Energy Calculator.

Open Energy CalculatorWe design and manufacture an extensive range of luminaires for a diverse number of sectors and applications. Whatever the shape, purpose or style of your space, we have a lighting solution.

View all sectors & applicationsView our latest product, OCTO smart lighting and application sector brochures.

Download our BrochuresFind information regarding our product warranty, product data downloads and FAQs regarding lighting and technical terms. Here you will find support with training CPDs as well as useful lighting design and LED strip calculators.

View the Energy CalculatorOCTO delivers the complete smart lighting package to transform the efficiency and ambience of commercial and residential spaces.

Download the BrochureFind product warranty details, data downloads, and lighting FAQs. Access training CPDs plus handy lighting design, energy and LED strip calculators—all in one place.

View the Energy CalculatorAztec range accessory additions

The design of external lighting applications which encompass the installation of lighting columns to support both single and multiple luminaire configurations is frequently an ideal solution for external lighting, however the specification of such installations is far from straightforward.

The design of the project starts with the lighting designer creating the proposed layout of the area space for the project, followed by the positioning of the floodlight luminaires into the calculation process, at the proposed mounting height, and with the appropriate orientation and inclination angle, so as to achieve the required illuminated solution.

Having completed the lighting design layout, it is then forwarded to the requesting electrical wholesaler, offering the details of the proposed luminaire(s) for illuminating the specified area, together with any additional bracketry. The lighting design will have been calculated based upon a specified luminaire height and equates to the height above ground level which the luminaire is to be placed upon an appropriate column. The information relating to the ‘windage’ of the face of the luminaire and the product weight, will have been provided with the lighting design by Ansell Lighting. The weight and windage of the bracket(s) used to attach the luminaire to the column must be included to achieve the total headweight values.

The task then falls to the electrical wholesaler upon receipt of the scheme, to specify and obtain suitable lighting columns for the proposed lighting equipment, which will be attached to the column within the installation. In doing so, the first point for the wholesaler to consider, is that a lighting column is deemed as being an engineered structural product which is manufactured with the capability to withstand both the physical forces of the total head-weight as well as offering protection against the environmental conditions, whilst providing both, an aesthetically pleasing appearance alongside minimal maintenance through operational life.

With regard to the lighting column, there are numerous different specifications of columns available, such as tubular, conical, hexagonal, octagonal, as well as ornamental, all of which are offered in a range of various heights and construction parameters. There are also a multitude of head frame attachments for the various floodlights, lanterns, or streetlights. With regard to the column construction, there is also a wide range of materials available for lighting columns, whether that be steel, aluminium, fibreglass, concrete, wood, or even composite, alongside a number of different foundation systems to secure the column in place.

An important attribute when considering an appropriate lighting column must be with its ability to withstand the combination of luminaire and bracketry projected area and total head weight against the adverse weather and windage conditions, by providing resistance against the forces being encountered over the expected life duration, which means that the specification and selection of each lighting column for the project is supported by engineering calculations to ensure the suitability of the column for the application in having the strength to safely accommodate the proposed luminaire configuration. In some applications, there may be unforeseen variances in the project design, and where this is the case, it is recommended to select a lighting column with additional capacity rather than one which just achieves the calculated specification.

When specifying the optimum lighting column, the value of windage is considered to be the Effective Projected Area (EPA) and is the exposed surface area of a luminaire to the wind, taking account of the shape factor or coefficient of drag of the luminaire, which is a variable value depending upon the shape of the luminaire, where a rectangular luminaire will present more resistance to the wind than a luminaire with a round or cylindrical profile. The EPA is equal to the area which is visible to the wind at a particular angle of orientation and inclination, however for many calculations, the area selected is normally that as being the maximum value of exposure and having calculated the windage for the luminaire, the value of windage of the mounting bracket is to be added, so as to achieve a combined and total EPA value, which is given in square metres (m²) of area.

To assist customers in lighting projects where a single floodlight is to be installed onto a single column, Ansell Lighting has added to the Aztec range of floodlights, single post-top brackets and column clamps for the most common tubular steel columns used in many commercial and industrial applications, that being for 76mm and 60mm diameter tubular steel lighting columns.

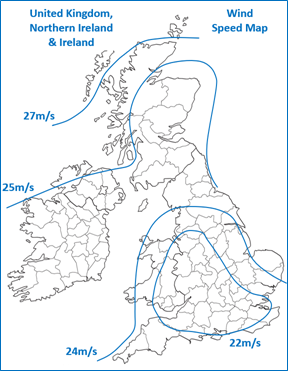

Having calculated the total head-weight and windage values for the column, then it is important to consider the geographical location in which the lighting column project is being installed and for the United Kingdom, Northern Ireland and Ireland, a ‘Wind Speed Map’ provides contour lines across the countries displaying the velocity of basic mean hourly wind speeds for the different locations, which have been expressed as being 27m/s, 25m/s, 24m/s and 22m/s (metres per second) where the values being shown are based upon wind speeds set at sea level and where the altitude of the location is above sea level, the mean hourly wind speed should be increased by 10% for every 100 metres of height above sea level, a figure which is then defined as being the ‘Site Mean Wind Speed’.

Whilst the Wind Speed Map provides general information, that of the steady wind velocity, which is expressed in metres per second (m/s) likely to occur in a specific location, and gust velocity, that being a momentary increase in wind causing a whipping action, however column manufacturers will have designed columns to withstand dead loads and predicted dynamic loads developed by variable wind speeds with an additional gust factor under certain application conditions, where the head weight includes the luminaire and mounting bracket and the column is installed within areas of known wind conditions. There could also be certain locations within the UK and Ireland where the magnitude of the local wind speed is deemed as being significantly affected by local conditions, thereby increasing the speed above the values shown in the diagram above, which may include locations within areas where hills and valleys or other usual geographic areas produce exceptional wind velocities. Calculating an accurate wind velocity for the specific location may necessitate the analysis of local meteorological conditions.

The total Effective Projected Area and the total Head Weight mounted onto the selected lighting column must never exceed the column’s maximum rating for the wind zone in which it is to be installed and all the calculations are normally based upon columns being installed in ground mounted applications, however where columns are mounted onto structures, such as the roof of a multi-storey car park, this will necessitate special consideration requiring consultation with a qualified structural engineer.

Finally, a regular planned maintenance schedule should be put in place for the external installation, where periodic inspection for normal deterioration and any indication of external or internal corrosion, as well as observation for excessive vibration.

NOTE: The specification and installation of appropriate columns for a lighting application falls outside of the area of expertise within Ansell Lighting, and therefore customers who require access to supporting information regarding specifying lighting columns, are suggested to make contact with a column manufacturer or secure the services of a structural engineer to obtain the criteria required.

You Might Also Be Interested In...