See how much you could save on energy costs with our easy-to-use LED Energy Calculator.

Open Energy CalculatorWe design and manufacture an extensive range of luminaires for a diverse number of sectors and applications. Whatever the shape, purpose or style of your space, we have a lighting solution.

View all sectors & applicationsView our latest product, OCTO smart lighting and application sector brochures.

Download our BrochuresFind information regarding our product warranty, product data downloads and FAQs regarding lighting and technical terms. Here you will find support with training CPDs as well as useful lighting design and LED strip calculators.

View the Energy CalculatorOCTO delivers the complete smart lighting package to transform the efficiency and ambience of commercial and residential spaces.

Download the BrochureFind product warranty details, data downloads, and lighting FAQs. Access training CPDs plus handy lighting design, energy and LED strip calculators—all in one place.

View the Energy CalculatorSurface spread of flame – TP(a) and TP(b)

The various Building Regulations place requirements upon the use of thermoplastic materials within buildings, with the principle of the restrictions being somewhat similar across each of the devolved countries of the United Kingdom, however the detail of implementation does vary somewhat between countries, where the documents containing the information are for England – Approved Document B on Fire Safety, for Wales – Approved Document B on Fire Safety, for Scotland – Technical Handbook, Section 2 on Fire, and for Northern Ireland – Technical Booklet E on Fire Safety.

In the process of providing a lighting solution for a new or refurbished building, two main aspects should be considered, that of Internal Fire Spread with regard to the Structure of the building which shall be designed and constructed so that, in the event of fire, its stability will be maintained, and that of the Internal Fire Spread with regard to inhibiting the Surface Spread of Flame within the building where the linings shall adequately resist the spread of flame over their surfaces. (Fire spread for the structure of a building is discussed elsewhere)

The various devolved Building Regulations place certain legal requirements upon the use of thermoplastic materials within a building, and to aid in complying with these legal requirements, national guidance documents expand upon the requirements and describe strategies in the use of thermoplastic materials TP(a) and TP(b) within building that are deemed to comply. The principle of the restrictions is fairly aligned, with variation in the detail of implementation.

PROTECTED STAIRWAYS & PROTECTED ZONES

For England, Wales and Northern Ireland, a protected stairway is a stair that leads to a final exit and to then a place of safety, that is adequately enclosed with fire resisting construction. This also includes the exit route between the stairs and the final exit of the building, where the final exit is the end of an escape route from a building which gives direct access to the outside and is sited so as to ensure that people can rapidly disperse away from the building and are no longer in danger.

For Scotland, it is a little more complex, in that a protected zone is the part of the escape route, which is within a building, but not within a room and to which access is only by way of a protected door where from there is an exit to a place of safety. The term ‘Protected Door’ means a fire door giving access to a protected zone including that of a protected lobby, or fire-fighting shaft, another compartment, place of safety, unenclosed external escape stair, open access balcony, or an escape route across a flat roof or access deck, whereas a ‘Place of Safety’ means in the open air at ground level, either, an unenclosed space or an enclosed leading to an unenclosed space, via access not narrower than the total width of the exits leading from the building to that enclosed space. A fire-fighting shaft is an enclosure protected from fire in adjoining accommodation and contains an escape stair, fire-fighting lobby at every storey at which the fire-fighting stair can be entered from the accommodation., where the stair may also contain a fire-fighting light together with its machine room. These shafts are used in high buildings, deep buildings and in certain shops and storage buildings to assist fire & rescue service personnel to carry out firefighting & rescue operations.

INTERNAL FIRE SPREAD – LININGS

The requirements for England and Wales are fairly well aligned in that for buildings other than dwellings, the detail in respect of the internal fire spread for linings, is to inhibit the spread of fire within the building, the internal linings shall adequately resist the spread of flame over their surfaces, and have, if ignited, either a rate of heat release or a rate of fire growth, which is reasonable in the circumstances, where the definition of ‘internal linings’ means the materials or products used in lining any partition, wall, ceiling or other internal structure. For Scotland, the detail in respect of the internal linings is that every building must be designed and constructed in such a way that in the event of an outbreak of fire within the building, the development of fire and smoke from the surfaces of walls and ceilings within the area of origin is inhibited. Finally, for Northern Ireland, and to inhibit the spread of fire within a building the internal linings shall offer adequate resistance to the spread of flame over their surfaces, and where they are located in a circulation space, have a low rate of heat release or a low rate of fire growth when ignited.

LIGHTING DIFFUSERS

The information contained within each of the documents of the various countries apply to thermoplastic materials used in light fittings with diffusers which form an integral part of a ceiling, and where these diffusers may be part of a luminaire or used below a recessed source of light, however the information does not apply to diffusers of light fittings either attached to the soffit of a ceiling or suspended beneath that ceiling where the ceiling structure remains intact.

The use of thermoplastic materials in ceilings, rooflights and lighting diffusers provides a significant hazard in a fire, where burning droplets can rapidly increase the fire growth rate and the smoke produced in a fire situation is normally dense and toxic, which combines to produce extremely hazardous conditions.

Thermoplastic material means any synthetic material that has a softening point below 200ºC when tested in accordance with BS EN ISO 306: 2004 – Method A120 Plastics, which determines the Vicat Softening Temperature (VST), and which is applicable only to thermoplastics, in giving a temperature measure at which thermoplastics start to soften rapidly.

Diffusers constructed of a thermoplastic material may be incorporated within ceilings to rooms and circulation spaces, but not to protected stairways, (protected zones or firefighting shafts in Scotland,) if both of the following conditions are met, where diffusers should be classified as being one of the following, either TP(a), where there is no restriction on their extent of use, or alternatively TP(b), where they are limited in their extent of use.

TP(a) LIGHTING DIFFUSERS

Lighting diffusers which have been tested in accordance with BS 2782-0 Method 508A and classified as being TP(a) rated, can be used in any space except for those of protected stairways or protected zones, such as those leading to a final exit, where the maximum area of each installed diffuser has no limit, but should be only to a maximum of 5m2.

The maximum total area of all the diffusers installed within the room (open area), as a percentage of the total floor area of the room, has no limit and the minimum separation distance between installed diffusers, again, has no limit.

TP(b) LIGHTING DIFFUSERS

Lighting diffusers which have been tested in accordance with BS 2782-0 Method 508A and classified as being TP(b) rated, can be used in rooms (open area), or circulation spaces, except for those of protected stairways and protected zones, such as those leading to a final exit, however, there is limitation on the extent of their use.

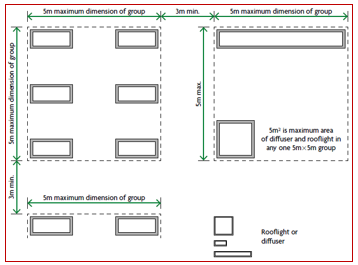

For both a room and for circulation spaces, the maximum area of each individual diffuser or group of diffusers has a limit of 5m2, however, smaller diffusers to be grouped together, provided that the overall size of the group as well as the space between one group and any others, is deemed to satisfy the dimensions.

Additionally, for both a room and for circulation spaces, there is a requirement to have a minimum 3 metre separation distance between each 5metre group, which must be maintained, and doing so, this may mean that the installation of the maximum percentages given is not possible. (See diagram below on the left)

For rooms, the maximum total area of all the diffusers installed within the room, as a percentage of the floor area of the room is not to exceed 50%. For circulation spaces, except protected stairways, the maximum total area of all the diffusers installed within the room, as a percentage of the floor area of the room is not to exceed 15%.

Within the building regulations, there is an alternative solution for installations with TP(b) diffusers relating to England, Scotland and Wales, but excluding Northern Ireland, in that the requirement is for rooms (open area) only, where the maximum area of each diffuser does not exceed 1m2, and where the maximum total area of all the diffusers installed within the room, as a percentage of the floor area of the room does not exceed 50%.

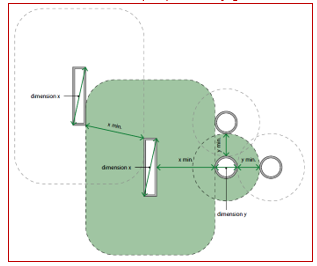

The configuration of thermoplastic lighting diffusers should be that the minimum separation distance between individual diffusers equates to a distance equal to the largest plan dimension of the largest diffuser, where on the ceiling plan, ‘X’ relates to the maximum dimension of the largest diffuser and ‘Y’, the maximum dimension of the smallest diffuser. The standards refer to the diffuser area and not the luminaire area. In practice, for square or rectangular fittings, the maximum distance is between opposing corners, and for circular fittings, is the maximum diameter, where these distances equate to the minimum edge to edge spacing distance of the nearest adjacent luminaires. (See diagram below on the right)

| Layout restrictions on class D-s3, d2 plastic rooflights,

TP(b) rooflights and TP(b) lighting diffusers |

Limitations applied to thermoplastic rooflights

and lighting diffusers in suspended ceilings and class D-s3, d2 plastic rooflights |

|

|

You Might Also Be Interested In...