See how much you could save on energy costs with our easy-to-use LED Energy Calculator.

Open Energy CalculatorWe design and manufacture an extensive range of luminaires for a diverse number of sectors and applications. Whatever the shape, purpose or style of your space, we have a lighting solution.

View all sectors & applicationsView our latest product, OCTO smart lighting and application sector brochures.

Download our BrochuresFind information regarding our product warranty, product data downloads and FAQs regarding lighting and technical terms. Here you will find support with training CPDs as well as useful lighting design and LED strip calculators.

View the Energy CalculatorOCTO delivers the complete smart lighting package to transform the efficiency and ambience of commercial and residential spaces.

Download the BrochureFind product warranty details, data downloads, and lighting FAQs. Access training CPDs plus handy lighting design, energy and LED strip calculators—all in one place.

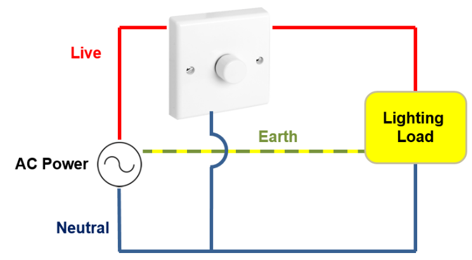

View the Energy CalculatorDimming AC Mains Phase Dimming

Dimming residential lighting allows the homeowner to achieve the desired levels of illumination within a room and consequently alter the mood of the environment. There are various types of dimming options available, however, the most popular system for a residential lighting installation is known as ‘Phase-cutting’ dimming.

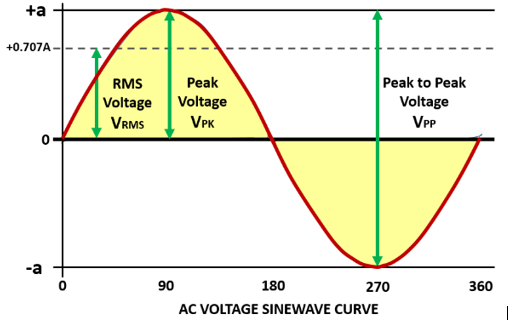

The technology used by Phase Dimmers works by ‘chopping’ out a part of the mains voltage to vary the RMS voltage fed to the light source and in doing so, this reduces the power being supplied, which results in a variation of the lamp brightness and this variation can be controlled by increasing or decreasing the RMS voltage and thereby provides the opportunity to control the brightness of the lamp.

Delaying the start of the phase cycle or prematurely ending each half-cycle of AC power is known as “phase control” which will regulate the amount of power to the lamp and this will occur very quickly, so that the majority of people will not detect any flicker, only seeing continuous dimming.

Essentially residential lighting dimmers are electronic switches that toggle on and off at the alternating current cycle rating of 50Hz which equates to passing through the zero point at 100 times per second.

There are two different types of phase control dimming, that is ‘Forward Phase Dimming’, commonly referred to as Leading-Edge Dimming and ‘Reverse Phase Dimming’, commonly referred to as Trailing-Edge Dimming. Each method works in a different way, therefore affecting their compatibility with certain light sources and dimmers.

Forward-Phase Dimming – (Leading Edge Dimming) (“Triac” Dimming)

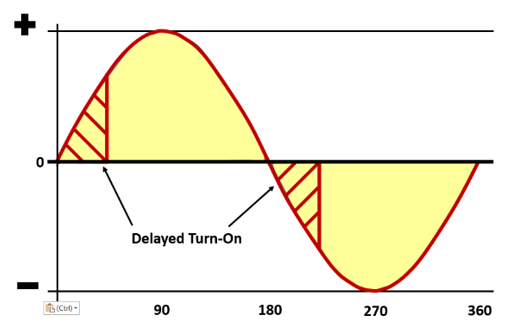

This is where the ‘chopping’ is carried out at the beginning of the AC Sinewave and this is suitable for inductive loads, such as those operating on magnetic low voltage transformers and resistive loads such as an incandescent light source. Leading-Edge Dimmers tend to be cheaper and simpler than that of Trailing-Edge Dimmers. Some Leading-Edge Dimmers can have a relatively high minimum load, which for small wattage LED’s may require multiple lamps or fittings to be installed onto a single lighting circuits, however Leading-Edge Dimmers is by far the more common Phase-Cut dimming control system.

Standard Forward Phase (Leading Edge) Dimmers change the voltage and current to the load by delaying the turn on every half wave, until the phase angle set by the dimmer control is reached. The Dimmer then naturally turns off at the current zero crossing and dimmers and they use a ‘TRIAC’ (Triode for Alternating Current) switch to control power and due to the characteristics of the semiconductor used, this form of dimming is generally referred to as ‘Triac Dimming’. This dimmer derives the phase angle to switch at, from simple circuitry, a capacitor charged through a variable Resistor within the Dimmer.

Some dimmers or electronic transformers specify the maximum number of lamps or lights sources which can be attached to the dimming product. This is a very rough way of keeping the maximum power factor within the limits of the dimmers trigger circuit. It offers no guarantees, especially considering the effect on the power factor when the lamp fails and it does not deal with the issues of spikes, audible noise or inducing Direct Current, however it is the most common method of dimming within residential installations.

Reverse-Phase Dimming – (Trailing Edge Dimming)

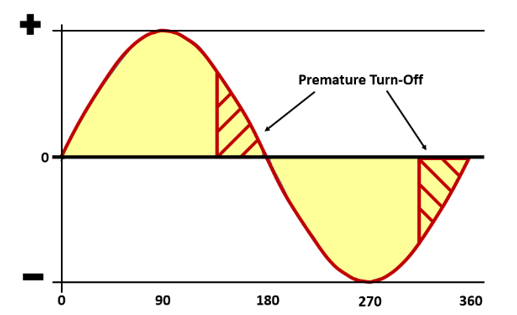

This is where the ‘chopping’ is carried out at the end of the AC Sinewave and this is suitable for capacitive loads such as those operating on electronic low voltage transformers and LED drivers and resistive loads such as an incandescent light source.

Standard Trailing Edge Dimmers change the voltage and current to the load by naturally turning on at the current zero crossing. The Dimmer then turns off prematurely before the end of the natural sine wave so that only part of the sine wave is transmitted, at a point when the phase angle set by the dimmer control is reached. This form of dimming has the term where it can be referred to as ‘ELV’ or ‘Low Voltage Dimming’.

Trailing-Edge Dimmers are more sophisticated than those of Leading-Edge dimmers in that they provide a much smoother dimming control, absent of any buzzing noise and has a lower minimum load than Leading-Edge Dimmer, making it an ideal solution for dimming the more modestly sized low-powered lighting circuits such as the residential application. The installation trailing edge dimmers is somewhat more complex if added to an existing lighting application, where only switching was provided, in that a Neutral supply between the dimmer and the power supply is required and this may involve additional electrical work to provide for that requirement.

The Trailing Edge Dimmer has no ability to allow for Power Factor within lighting circuit, however, having no sharp rising edges of current in the circuit, the basic Trailing Edge Dimmer does solve the issues of spikes & often audible noise being purpose built to control capacitive loads and they also do not have an inductor. By the nature of their design Trailing Edge Dimmers turn the current off and therefore it is impossible for them to produce spikes.

Lighting Considerations

Unlike incandescent light sources, which are dimmable by default, an LED light source operates through an electronic driver, either remote or built-in, to drive the lamp or fitting. The LED Driver converts the AC Power to that of DC Power and maintains a constant current to the LED. This can be at odds with a Phase Control Dimming System, in that the LED Driver may attempt to compensate for the ‘chopped-out’ portions of the sinewave voltage curve.

LED luminaires usually include a remote LED Driver, pre-wired by cable from the light source which can be either of the ‘Constant Current’ or ‘Constant Voltage’ type, depending upon the specification of the LED array. In both cases the same issue can arise in that the LED Driver may attempt to ‘patch up’ the missing parts of input Voltage and where these LED compatibility issues exist. Some LED’s and their Dimmable LED Driver will only operate with selective Dimming Control Systems, where issues are generally seen as being, either flickering, flashing, or dead travel.

For an LED lamp or luminaire to work with a Phase Control Dimmer, the electronics of its driver must be compatibly adapted. Leading-Edge Dimmers are sometimes called ‘Incandescent Dimmers’ because they were originally designed to handle the resistive load of incandescent light sources.

Many existing dimmer switches may tend to have high minimum loads for operation and with the multitude of LED lamps and light sources being of low wattage, this may necessitate the installation of a number of LED light sources into a single circuit in order to have the opportunity of the dimming option working acceptably. It is therefore most important that the compatibility of the lighting circuit is matched with a suitable lighting control system to alleviate the potential issues.

You Might Also Be Interested In...