See how much you could save on energy costs with our easy-to-use LED Energy Calculator.

Open Energy CalculatorWe design and manufacture an extensive range of luminaires for a diverse number of sectors and applications. Whatever the shape, purpose or style of your space, we have a lighting solution.

View all sectors & applicationsView our latest product, OCTO smart lighting and application sector brochures.

Download our BrochuresFind information regarding our product warranty, product data downloads and FAQs regarding lighting and technical terms. Here you will find support with training CPDs as well as useful lighting design and LED strip calculators.

View the Energy CalculatorOCTO delivers the complete smart lighting package to transform the efficiency and ambience of commercial and residential spaces.

Download the BrochureFind product warranty details, data downloads, and lighting FAQs. Access training CPDs plus handy lighting design, energy and LED strip calculators—all in one place.

View the Energy CalculatorFire Rated Downlights

Electrical Safety First, the UK’s leading charity on fire safety, recommends that fire rated downlights (FRDs) are installed in any ceilings where recessed lights are specified.

This is obviously sound health and safety advice – FRDs have in-built protection that prevents fire and smoke spreading in the event of a blaze.

However, the Building Regulations and National Housebuilding Council (NHBC) standards relating to recessed lights are complex and can be misunderstood, so much so that last year the NHBC felt it necessary to clarify the guidance to builders and developers in an effort to strengthen compliance with fire resistance standards.

Equally complex are the three fire resistance ratings, of 30, 60 and 90 minutes, which indicate the length of time a complete floor-ceiling structure must be able to withstand fire to enable the evacuation of people and prevent the rapid spread of flames and smoke.

These differ according to the structure of a building and how many floors it has so, for example, the ceiling of a typical semi-detached house will require a lower fire rating than one at the top of a high rise tower block or offices, and if a structure has a 90 minute rating that does not mean it is automatically covered for a 30 or 60 minute rating.

Additionally, there are distinct specifications of ceiling thickness and joist spacing according to each time category, and these vary according to the different types of joist in use.

Therefore, understanding a building’s fire resistance ratings and the specific requirements relating to different types of ceiling joist is essential when specifying downlights.

There are three types of joist to consider – solid timber, I-Joist and metal web/open web (commonly called the Posi Joist).

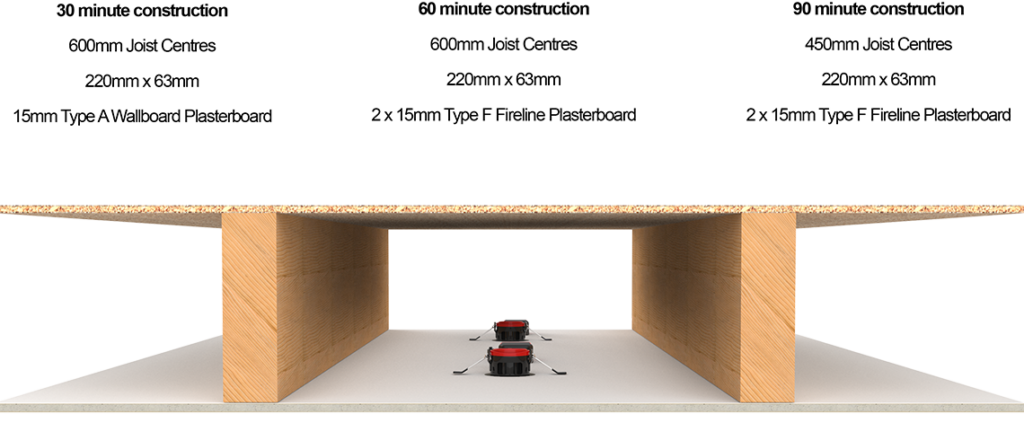

Solid Timber Joist

The most traditional of all ceiling joists, the solid timber joist is typically only seen in domestic dwellings which were constructed more than 20 years ago, though you will also see them used within internal floor and separating constructions for both residential and commercial applications.

Specifications for each fire resistance rating category are:

30 minute construction

- 600mm joist centres

- 220mm x 63mm

- 15mm Type A wallboard and plasterboard

60 minute construction

- 600mm joist centres

- 220mm x 63mm

- 2 x 15mm Type F Fireline plasterboard

90 minute construction

- 450mm joist centres

- 220mm x 63mm

- 2 x 15 mm Type F Fireline plasterboard

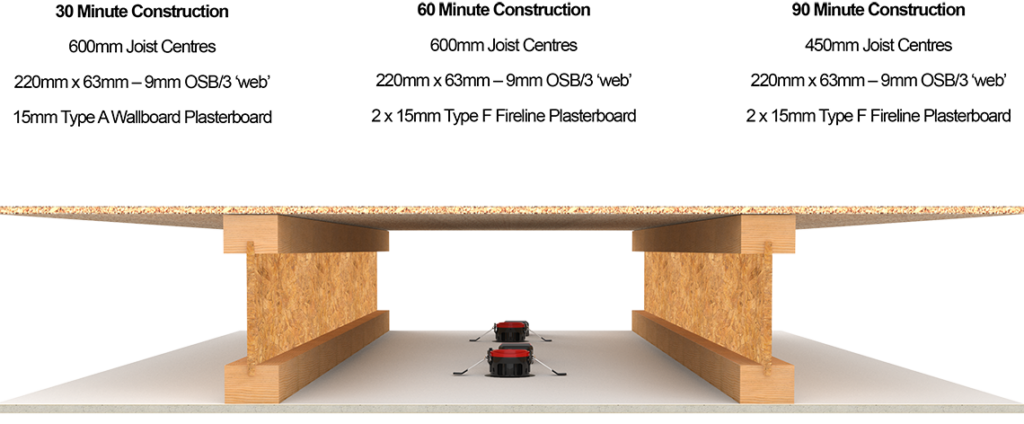

I-Joist

A lightweight joist designed for domestic applications, I-Joists now dominate the house-building market and are used on new builds across the UK. They have greater strength-to-weight ratio compared to other options, which accounts for their continued growth in popularity.

Specifications for each fire resistance rating category are:

30 minute construction –

- 600mm joist centres

- 220mm x 63mm – 9mm OSB/3 ‘web’

- 15mm Type A Wallboard plasterboard

60 minute construction –

- 600mm joist centres

- 220mm x 63mm – 9mm OSB/3 ‘web’

- 2 x 15mm Type F Fireline plasterboard

90 minute construction –

- 450mm joist centres

- 220mm x 63mm – 9mm OSB/3 ‘web’

- 2 x 15mm Type F Fireline plasterboard

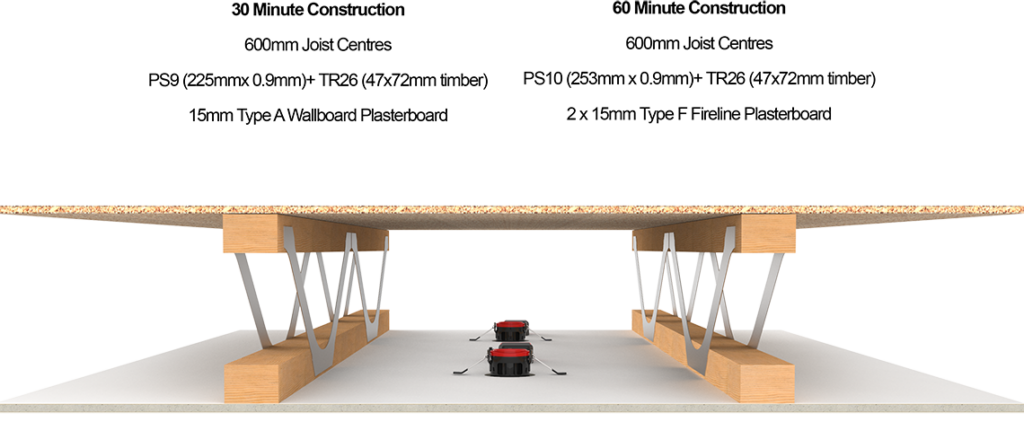

Metal Web/Posi Joist

The Posi Joist (metal web/open web) is a new joist type used in the UK. It combines the lightness of timber with the strength of the Posi Strut steel web, which enables it to span far greater distances. The Posi Joist can be used across a wide range of applications, for both floor and roof, in domestic, industrial and commercial applications. It is not used in 90 minute construction applications.

Specifications for the relevant fire resistance rating categories are:

30 minute construction –

- 600mm joist centres

- PS9 (225mm x 0.9mm) + TR26 (47mm x 72mm timber)

- 15mm Type A Wallboard plasterboard

60 minute construction –

- 600mm joist centres

- PS10 (253mm x 0.9mm) + TR26 (47mm x 72mm timber)

- 2 x 15mm Type F Fireline plasterboard

Ensuring compliance

It is essential to guarantee that the fire rated downlights installed meet the requirements of Building Regulations and the NHBC.

Selecting the right FRD can be made simple by selecting a model which complies with every category of the joist specifications. Ansell Lighting is the only manufacturer to offer a range of FRDs that can be used across all ceiling types, including the Ansell Prism Pro and Edge Quad/Pro FRDs, which can be specified for every joist type and every fire resistance rating.

These (and other FRDs in the range) come with full documentation of relevant testing, including test house certification numbers, to provide absolute confidence that the downlight will offer maximum protection to the people inside a building, and the structure itself, in the event of a fire.

They also meet the requirements of Part B Fire Safety, Part C Moisture Protection, Part E Acoustic Resistance and Part L (One and Two) Energy Efficiency Building Regulations.

It is the responsibility of the lighting manufacturer to evidence that a FRD is fully compliant. When specifying any FRD, proof of certification should be established, to avoid inaccurate specification or the risk of purchasing cheaper imports which might not be fully compliant.

Responsibility for fire safety in buildings is, ultimately, a collective industry-wide concern. Sharing knowledge to ensure best practice and compliance with the often complex requirements associated with building construction and lighting installation can only benefit us all

You Might Also Be Interested In...